Hy-Lok USA, Inc. double ferrule compression tube fittings provide leak-free performance for the most demanding applications.

Two ferrule tube fittings are designed and manufactured to meet the rigorous specifications required of industrial applications. Hy-Lok tube fittings are commonly used throughout the oil and gas, pulp & paper, petro-chemical/chemi

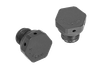

Available in numerous configurations and sizes, our tube fittings are made up of four parts consisting of a body, front ferrule, back ferrule, and nut. Outstanding leak-tight connections are consistent as the two-ferrule design compensates for any tolerances in tube outer diameter, wall, thickness, and material hardness.

Hy-Lok tube fittings feature a low torque assembly and positive leak free seal for easy assembly and reassembly. During installation the mechanical properties of the tubing are maintained because the back ferrule moves in a controlled manner that does not stress or reduce the inner diameter of the tubing. Since the front ferrule does not force the body to expand the nut can be backed off easily for disassembly and remakes.

Constructed of standard materials including 316 stainless steel, brass, and Monel, other materials such as duplex stainless steel, titanium, and carbon steel are available upon request. Heat code traceability for 316 stainless steel and Alloy 400 assures the ratings and quality of each fitting and accounts for code requirements.

Fitting size range from 1/16″ thru 2″ (2 mm thru 38 mm O.D.tubing) with numerous choices in end connections and patterns. They are rated to the maximum working pressure of the recommended tubing. Hydraulic swaging tools (EZY-MAT) are provided for easy installation.

Hy-Lok tube fittings are manufactured to Hy-Lok’s stringent quality control program and standards which assure the highest quality available in the industry. We are a global industry leading provider of fitting solutions and have obtained ASME Quality and ISO 9001:2008 Certifications.

To fulfill the need for leak-free gas and fluid containment, our tube fittings are the ideal solution.

| Hy-Lok USA, Inc. | |

|---|---|

| Product Category | Gas Fittings |

| Product Name | Hy-Lok Tube Fittings |

| Fitting Type | Tube Fitting; Bulkhead Fitting (optional feature); Elbow Fitting; Cross 4-Way Fitting (optional feature); Tee Fitting (optional feature); Union Fitting (optional feature); Adapter Fitting (optional feature); Reducer Fitting (optional feature) |