Specifications

AWS A5.27 Class RBCuZn-B

ASME SFA5.7 Class RBCuZn-B

QQ-R-571C, MIL-R-19631B

Type RcuZn-B

Description

Washington Alloy Nickel Bronze (also referred to as Manganese Bronze) is similar to Naval Bronze, however iron, manganese and nickel have been added to the analysis. The iron and manganese increases the hardness and strength of the weld deposit while nickel ensures uniform distribution of iron in the deposit. Nickel Bronze is primarily used to braze or oxyacetylene weld steel, cast iron, brass and bronze. Also used for building-up wearing surfaces and bearings. Flux required. Use a boric acid or borax commercial flux. A neutral or slightly oxidizing flame should be used. Preheating may be required for some applications.

Specifications

AWS A5.27 Class RBCuZn-B

ASME SFA5.7 Class RBCuZn-B

QQ-R-571C, MIL-R-19631B

Type RcuZn-B

Description

Washington Alloy Nickel Bronze (also referred to as Manganese Bronze) is similar to Naval Bronze, however iron, manganese and nickel have been added to the analysis. The iron and manganese increases the hardness and strength of the weld deposit while nickel ensures uniform distribution of iron in the deposit. Nickel Bronze is primarily used to braze or oxyacetylene weld steel, cast iron, brass and bronze. Also used for building-up wearing surfaces and bearings. Flux required. Use a boric acid or borax commercial flux. A neutral or slightly oxidizing flame should be used. Preheating may be required for some applications.

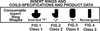

| Washington Alloy Co. | |

|---|---|

| Product Category | Filler Alloys and Consumables |

| Product Number | UNS/CDA C68000 NICKEL BRONZE ALLOY NO. 680 |