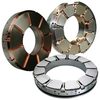

Waukesha Bearings tilt pad thrust bearings, available with or without equalizing links, are designed to transfer high axial loads from rotating shafts with minimum power loss, while simplifying installation and maintenance.

Patented design features allow for optimized performance in a variety of applications and address industry-wide challenges such as axial vibration.

Each bearing consists of a series of pads supported in a carrier ring (retainer). Each pad is free to tilt, resulting in a self-forming hydrodynamic film. The self-equalizing design balances the load between the pads and accommodates misalignment or deflection between the bearing and collar.

The carrier ring may be in one piece or in halves, and the size and number of pads are selected to suit the operating conditions. In addition, pads can be supplied with center pivots for bi-directional running or offset pivots for increased load capacity and lower pad temperatures.

Temperature sensors are typically installed in two pads per thrust bearing.

Advantages

Proven designs for non-equalizing and self-equalizing tilt pads

Compact designs to save space

Pad number, pivot offset and pad material designed to suit specific application

Pad optimization provides low frictional drag and improved oil circulation

Industry-standard ‘Directed Lubrication’

Waukesha Bearings tilt pad thrust bearings, available with or without equalizing links, are designed to transfer high axial loads from rotating shafts with minimum power loss, while simplifying installation and maintenance.

Patented design features allow for optimized performance in a variety of applications and address industry-wide challenges such as axial vibration.

Each bearing consists of a series of pads supported in a carrier ring (retainer). Each pad is free to tilt, resulting in a self-forming hydrodynamic film. The self-equalizing design balances the load between the pads and accommodates misalignment or deflection between the bearing and collar.

The carrier ring may be in one piece or in halves, and the size and number of pads are selected to suit the operating conditions. In addition, pads can be supplied with center pivots for bi-directional running or offset pivots for increased load capacity and lower pad temperatures.

Temperature sensors are typically installed in two pads per thrust bearing.

Advantages

- Proven designs for non-equalizing and self-equalizing tilt pads

- Compact designs to save space

- Pad number, pivot offset and pad material designed to suit specific application

- Pad optimization provides low frictional drag and improved oil circulation

- Industry-standard ‘Directed Lubrication’